Services

Machine tool renovation

Renovating machine tools is essential in order to improve production efficiency and reduce costs. Using modern technologies and expert knowledge, old machines are given new life and meet the strictest industry standards. Careful refurbishment extends the life of machines, improves their performance and reduces the risk of breakdowns. As a result, production processes become more efficient, resulting in significant savings in the long run.

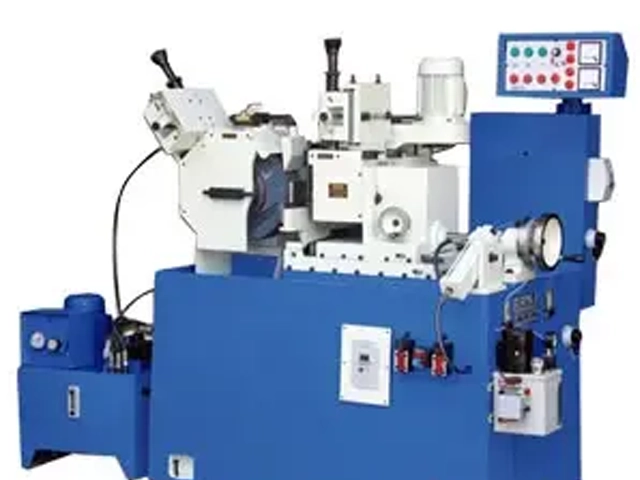

Grinding machine renovation

The renovation of the grinding machine provides an opportunity to restore the old equipment to its optimal performance, ensuring accurate and efficient material processing. During the refurbishing process, machine parts are upgraded, repaired or replaced, which increases its life and performance. Refurbishment of grinding machines helps reduce downtime, maximize productivity, supporting cost-effective operation and sustainable industrial solutions.

Renovation of an eccentric press

Renovating eccentric press machines is an effective solution for restoring the original performance required for precision metalworking. During renovation, worn parts are repaired, replaced and modernized, increasing production capacity and reducing downtime. The modernization of the eccentric press ensures a longer service life and more reliable operation, supporting cost-effective and sustainable production processes.

CNC control replacement

Replacing the CNC control system is essential for machines where the old control is outdated or not performing properly. Modernizing the control system not only increases productivity, but also ensures precise machining and reduces the likelihood of errors. Modernization of the control system enables the automation of production processes, improves cost efficiency, while also extending the life of the machines.

Automation

The design and production of automation systems plays a key role in increasing the efficiency of machine tools. With the development of support units and the introduction of automation solutions aimed at reducing cycle times, production processes become faster and more precise. These modern solutions not only increase productivity, but also contribute to cost-effective operation.